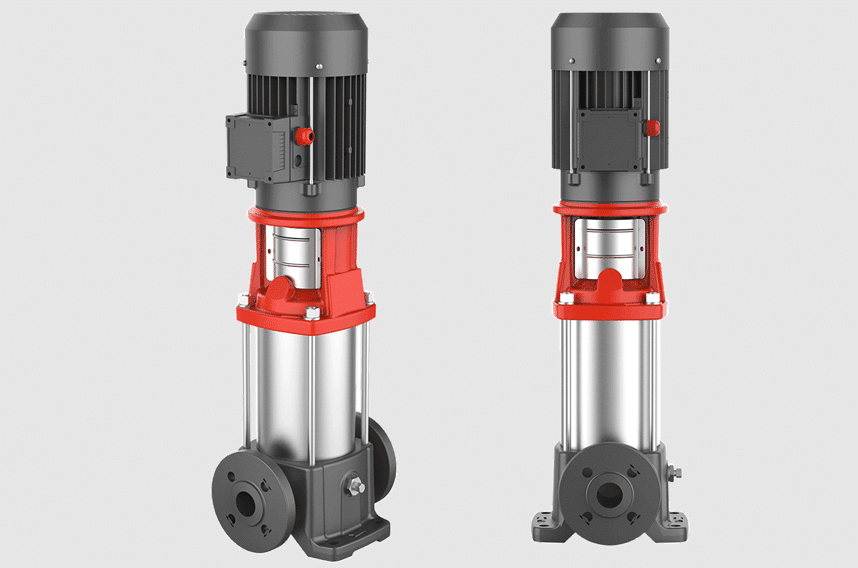

Vertical multistage pump working principle

As an efficient and reliable fluid transfer equipment, vertical multistage pump plays a vital role. Its unique design and excellent performance, so that it can show excellent transmission efficiency and stability in a variety of complex conditions, become one of the indispensable equipment in many industries. This paper will deeply discuss the working principle, structural characteristics, application fields and maintenance knowledge of vertical multistage pump, in order to provide a valuable reference for practitioners in related industries.

The working principle of vertical multistage pump

Vertical multistage pump, as the name suggests, means that the pump shaft is installed perpendicular to the ground, and is composed of multiple impellers in series, each impeller can pressurize the fluid once, so as to achieve the effect of multistage pressurization. When the motor drives the pump shaft to rotate, the fluid is sucked into the inlet at the bottom of the pump body, and gradually accelerates and increases the pressure through the rotation of the impeller at all levels, and finally outputs the high pressure from the outlet at the top of the pump body. This process not only increases the head of the fluid, but also ensures a stable flow output.

Structural characteristics

Vertical structure: small footprint, easy to install and maintain, especially suitable for limited space occasions.

Multistage supercharging: Through the series of multistage impellers, the fluid lift can be effectively improved to meet the needs of high lift and small flow.

Sealing system: mechanical seal or packing seal is usually used to effectively prevent leakage and extend the service life of the pump.

Bearing and lubrication: The use of high-quality bearing and lubrication system to ensure long-term stable operation of the pump.

Material selection: According to the characteristics of the conveying medium, stainless steel, cast iron and other materials can be selected, with strong corrosion resistance.

Application field

Vertical multistage pumps are widely used in the following fields:

Water treatment: Used for urban water supply, sewage treatment, seawater desalination and so on.

Petrochemical: Transport a variety of corrosive, flammable and explosive liquids.

Power industry: cooling water circulation, boiler feed water, etc.

Mine metallurgy: mine drainage, tailings transportation, etc.

Agricultural irrigation: Improve water sources for efficient irrigation.

Maintenance

In order to ensure the long-term efficient operation of vertical multistage pumps, regular maintenance and maintenance is essential:

Regular inspection: Check bearing temperature, vibration, and wear of seals.

Cleaning and lubrication: regularly clean the inside of the pump body, replace or replenish the lubricating oil, and keep the lubrication system clean.

Replacement of wearing parts: seal leakage, bearing damage, etc. should be replaced in time.

Electrical inspection: Check motor windings, cable connections, etc., to ensure that the electrical system is safe and reliable.

Shutdown protection: When not in use for a long time, the pump should be treated with rust prevention and moisture resistance to avoid motor moisture.

Conclusion

The vertical multistage pump has become an important equipment in the field of modern industrial fluid transmission because of its unique design advantages, wide application fields and efficient performance. With the continuous progress of technology and the deepening of applications, vertical multistage pumps will play an important role in more fields and promote the sustainable development of related industries. For users, mastering its working principle, structural characteristics, and doing daily maintenance is the key to ensure efficient and stable operation of the pump group. In the future, vertical multistage pumps will continue to develop in the direction of more efficient, more intelligent and more environmentally friendly, creating more value for human society.