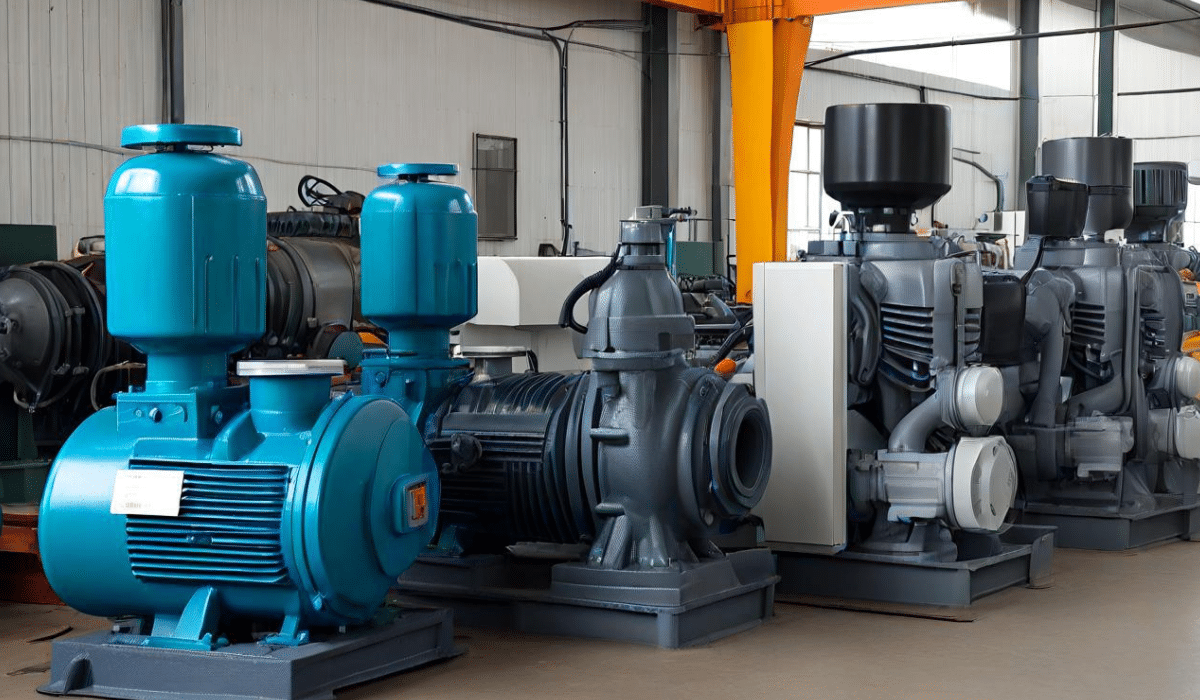

Different types of water pumps

In many fields such as industrial production, agricultural irrigation, urban water supply and household water, the pump plays a pivotal role as a key fluid transport equipment. With the advancement of science and technology and the diversification of demand, the types of pumps are increasingly rich, and each type of pump is designed for specific application scenarios to meet different transportation needs. This article will discuss several common pump types and their applications in depth.

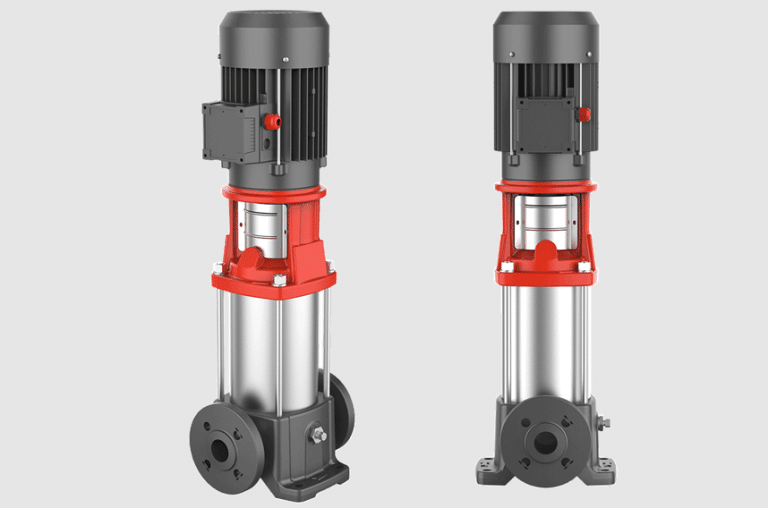

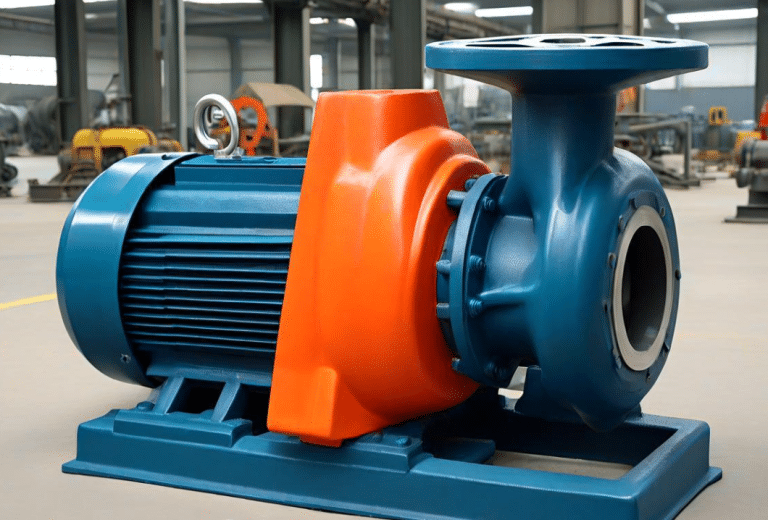

Centrifugal pump: widely used “heart”

Centrifugal pumps are the most common and basic type of water pump family. Its working principle is based on the role of centrifugal force, when the impeller rotates at high speed, the liquid is sucked into the center of the pump body, and then thrown around to form a high-pressure liquid from the outlet. Because of its simple structure, easy maintenance and high efficiency, centrifugal pumps are widely used in many fields such as urban water supply, industrial cooling and farmland irrigation. In particular, the multi-stage centrifugal pump, by connecting multiple impellers, can significantly improve the head to meet the needs of high-rise buildings or long-distance water transmission.

Axial flow pump: large flow, low head is preferred

The biggest difference between axial flow pump and centrifugal pump is that the direction of fluid flow is basically consistent with the axis of the impeller. Axial flow pumps are mainly used for occasions requiring large flow and low head, such as river water lifting, flood discharge, and large-scale irrigation of farmland. Because of its compact structure and light weight, axial flow pumps are particularly popular in areas with abundant water resources.

Mixed flow pump: between centrifugal and axial flow

Mixed flow pump combines the characteristics of centrifugal pump and axial flow pump, its fluid is neither completely radial like centrifugal pump, nor completely axial flow like axial flow pump, but between the two, so the name mixed flow pump. This design makes the mixed flow pump perform well in the case of medium head and flow, and is widely used in farmland irrigation, urban drainage and industrial circulating water systems.

Submersible pump: the master of underwater operation

Submersible pump is a pump designed to work directly into the water, its motor and pump body integration, good sealing, can be long-term stable underwater operation. Submersible pump is suitable for deep well water intake, pond sewage, underwater operation platform cooling cycle and other scenarios, its biggest advantage is to reduce the ground installation space, improve the efficiency of the operation.

Shielded pump: a safe choice without leakage

Shielded pump, also known as non-leakage pump, is characterized by complete isolation of the motor and pump body, through static sealing instead of dynamic sealing, effectively avoiding the problem of liquid leakage. This design is especially suitable for conveying toxic, harmful, flammable and explosive or corrosive liquids, such as raw material transportation in chemical production, circulation cooling in petroleum refining process, etc.

Summary

There are many types of pumps, each with its own unique advantages and application areas. Choosing the right pump is not only related to the efficiency and quality of fluid delivery, but also directly affects the safety, stability and maintenance costs of the equipment. Therefore, in the purchase of water pumps, should fully consider the use of scenarios, liquid characteristics, head demand, flow requirements and budget and other factors, comprehensive assessment to make the best choice. With the advancement of technology, the future pump industry will be more intelligent and efficient, providing more accurate and reliable fluid transport solutions for all walks of life.