The water pump control panel is the electrical equipment used to control the operation of the pump, which plays an important role in many fields.

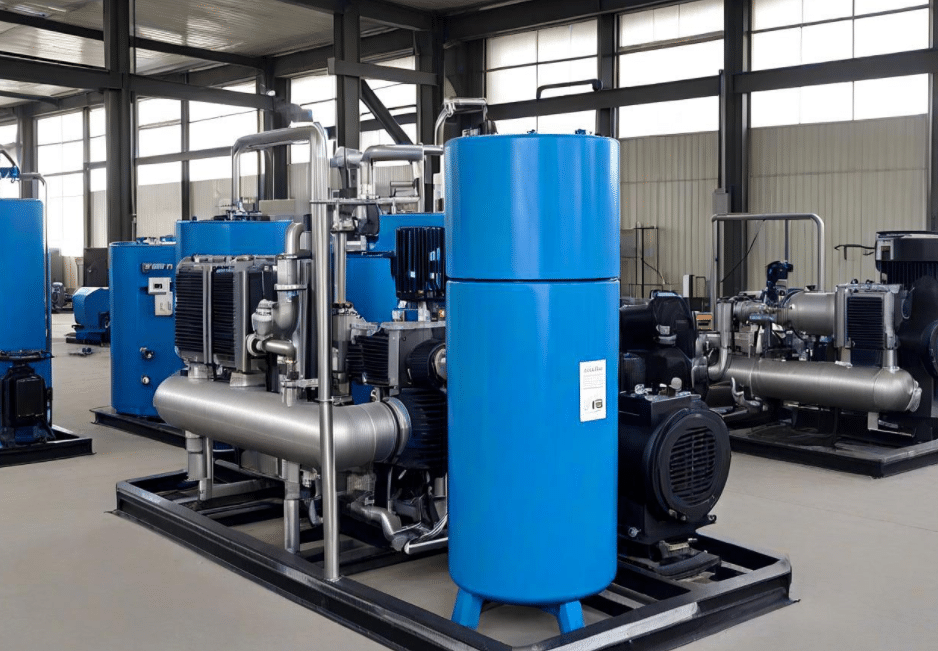

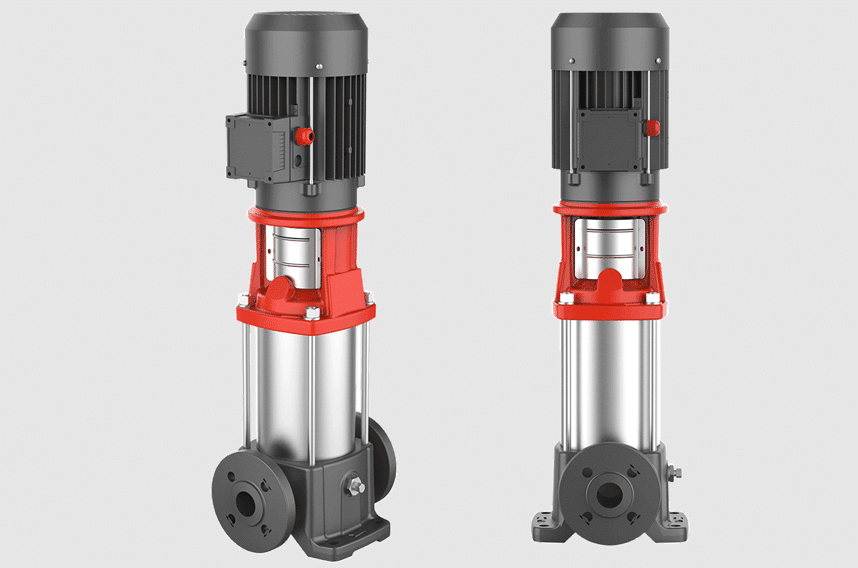

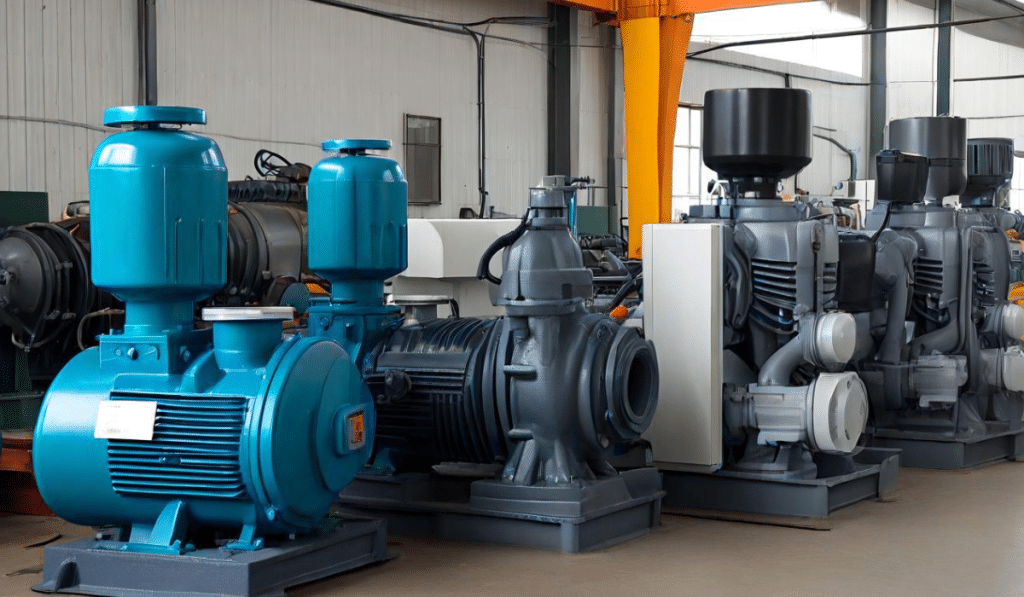

Pump control cabinet is mainly suitable for industrial and agricultural production and all kinds of building water supply, drainage, fire, spray pipe network pressurization and HVAC cold and hot water circulation and other occasions of automatic pump control.

It has overload, short circuit, lack of phase protection and pump body water leakage, motor overtemperature and leakage protection functions, and has a complete state display. In addition, the pump control cabinet also has a single pump and multi-pump control mode, a variety of main and standby pump switching modes and various starting modes.

Control type and startup mode

Type of control

- Liquid level control: The control cabinet is equipped with a high-performance float switch, which automatically controls the opening and stopping of the water supply and drainage pump according to the high and low changes of the liquid level.

- Pressure control: the external electric contact pressure gauge or pressure controller can automatically open and close the pump according to the change of the pipe network pressure. This type is widely used in domestic water supply and fire pressurization system.

- Temperature control: external temperature controller, according to the set temperature range to open or close the pump, used in constant temperature, heat exchange system and other temperature control occasions.

- Time control: The panel of the chassis is provided with a time setting button and display, the user can control the opening and closing of the pump according to the timing needs, which is suitable for a variety of periodic or regular intermittent working mode control.

Starting method

- Full pressure start: directly start the pump.

- Star triangle buck starting: The star triangle transformation reduces the starting current.

- Autobuck starting: The starting current is reduced by the autotransformer.

- Soft start: Gradually increase the motor starting current through the soft starter.

- Frequency conversion start: The motor speed is controlled by the frequency converter to achieve smooth start.

Main loop and protection function

The main circuit of the pump control cabinet is composed of isolation circuit, short circuit protection, overload (backup) protection circuit, start-stop (variable speed) control electrical apparatus, thermal relay and distribution wire and cable, etc., to form an effective protection of the pump motor. It also has a variety of protection functions, such as overload, short circuit, phase loss protection, pump body water leakage, motor overtemperature and leakage, etc., to ensure the safe operation of the pump system

Typical application

- Constant pressure water supply system

- Fire fighting system (including control cabinet for fire hydrant, control cabinet for automatic spray and control cabinet for fire stabilizing pump, etc.)

- Spray system

- Central air-conditioning system

- Water supply and drainage system

- Port machinery, machine tools, boilers and other industrial fields

- Paper making machinery, food machinery and other production equipment

| Product Name | Water Pump Control Panel |

| Brand | YH |

| Model Number | / |